Product: TS Range

Features:

- Max temp 1200°C

- Heated lengths 400 - 1200 mm

- Furnace Ø 125 mm

- Orientation Horizontal / vertical

Product: FST / FZS (F-A)

Features:

- Max temp 1300 °C

- Heated lengths 200 - 4500 mm

- Furnace Ø up to 200 mm

- Orientation Horizontal / vertical

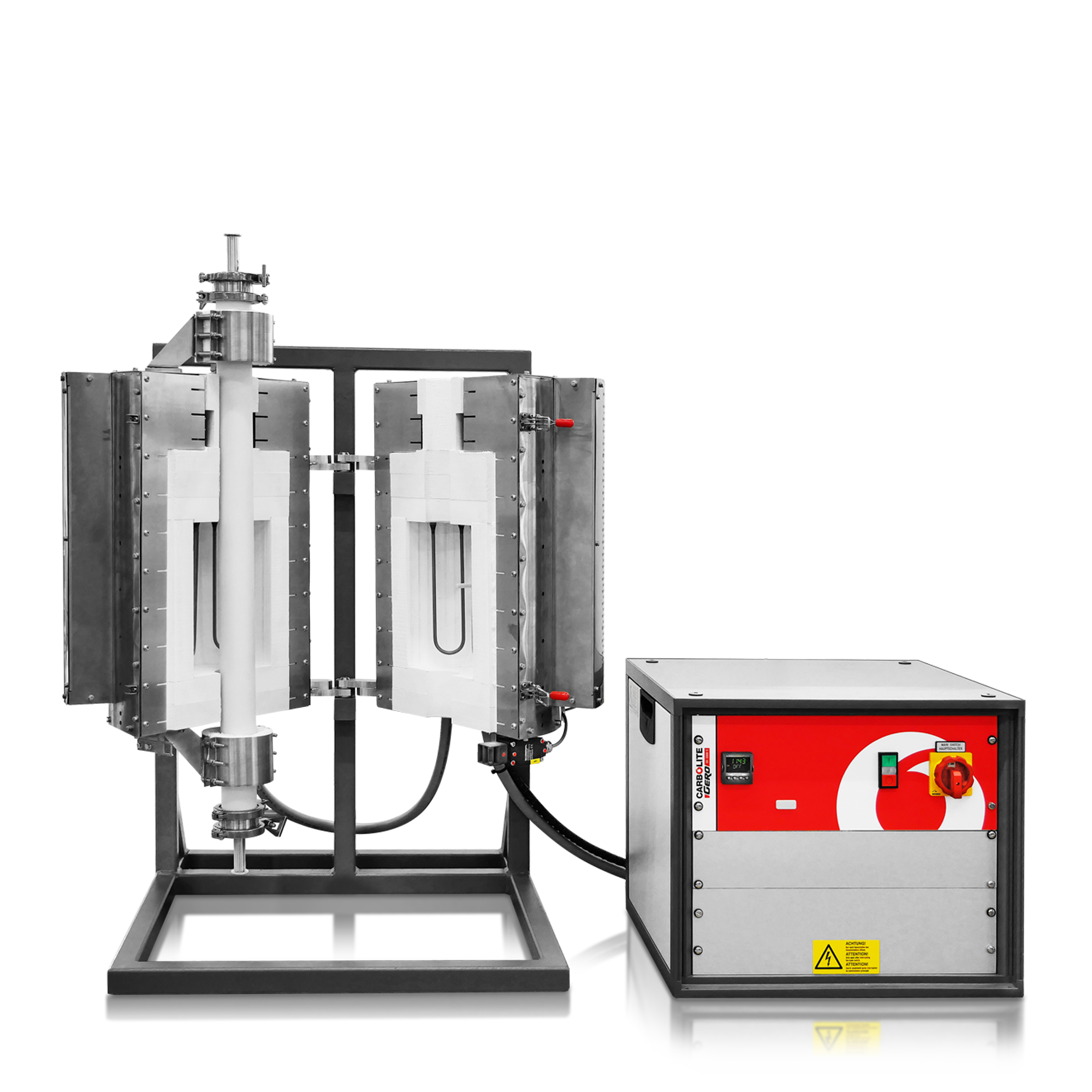

Product: HTRV-A

Features:

- Max temp 1600, 1700 °C

- Heated lengths 120 - 500 mm

- Furnace Ø up to 70 mm

- Orientation Vertical

Scharnierende Buisovens - FAQ

What is a split tube furnace?

A split tube funace is a tube furnace that can be opened to allow for the easy installation and removal of work tubes and reaction vessels. Carbolite's TS split tube furnace range is constructed in two halves, joined together with hinges, and fitted with pneumatic dampening struts for ease of opening.

What is the benefit of a split tube furnace?

The main benefit of a split tube furnace is the ability to open the furnace to allow the easy installation and removal of work tubes and reaction vessels with ends and fittings that would otherwise be impossible to fit into a non-split tube furnace.

Which applications require a split tube furnace?

There are numerous applications where it is beneficial to use a split tube furnace as the process of installing and removing is made much easier and faster than with a non-split furnace. Rotating, oscillating and gradient tube furnaces all incorporate a split design. Split tube furnaces are frequently used in applications such as the tensile testing of materials, pyrolysis, chemical vapour deposition, graphitisation etc.

Can a split tube furnace be used horizontally and vertically?

With the correct accessories, split tube furnaces can be used both horizontally and vertically.